Constant force spring belongs to a broad category in spring. With the progress and development of science and technology, constant force spring has been widely used.

Constant force spring refers to a kind of spring, which is zero stiffness and constant tension or torque when applied.

It features a more massive force output in smaller spaces requiring minimal startup and energy storage when stretching.

Rolling steel strips make winding.

External force rolls off the spring from the natural state to the output wheel.

When external force removes wind, the winding will roll back the natural state, simultaneously produces fixed torsion at the output wheel, therefore, call torsion spring.

Torque winding is better than power spring: torque does not change due to increased rotation cycles.

There is no limit to the number of cycles.

Multiple rotating circle number design adopts fixed torsion spring; an invalid circle number is few, can store more energy, efficiency is higher.

Fixed torque winding can be applied to collecting line balancing heavy objects power source USB automatic coil device non-pull rope curtain and fixed torque winding generator radio.

Manufacturing range: thickness 0.06 ~ 0.5 mm and width 1.0 ~ 50 mm.

The constant force spring is used in motor carbon brushes. The advantage is concentration, regardless of brush length, is maintained at the same pressure as the rectifier.

Reduce friction consumption of carbon brush, increase carbon brush lifetime, and reduce current loss.

Miniaturization of design, reducing outer motor diameter.

Increase carbon brush length.

More massive rectifiers can be used.

Reduce spark and reduce electromagnetic interference (EMI).

Manufacturing range: thickness 0.05 ~ 0.5 mm and width 1.0 ~ 50 mm.

The winding wind is one kind of vortex winding, also called power spring.

It works when we pull wires out of special boxes that fix lines, using wind torque to automatically retract them into tubes, winding boxes limit the outer diameter, connecting shafts with power shafts, rotating shafts and springs when pulling out, wind up on power shafts and store kinetic energy. When external forces disappear, wind springs generate torque drive shafts. So that lines can be recovered into boxes.

Wind spring is also rolled by steel strips, unlike the force spring, it has a winding box limiting its outer diameter.

Wind spring can be divided into predetermined force winding and dynamic wind spring. Its advantages in industrial applications are mainly manifested as follows:

1. Short stretch stroke.

2. Regardless of the extent of external force stretching, its elasticity is constant.

3. Long service life.

4. Compared with the force, spring can store more than 25% to 55% torque.

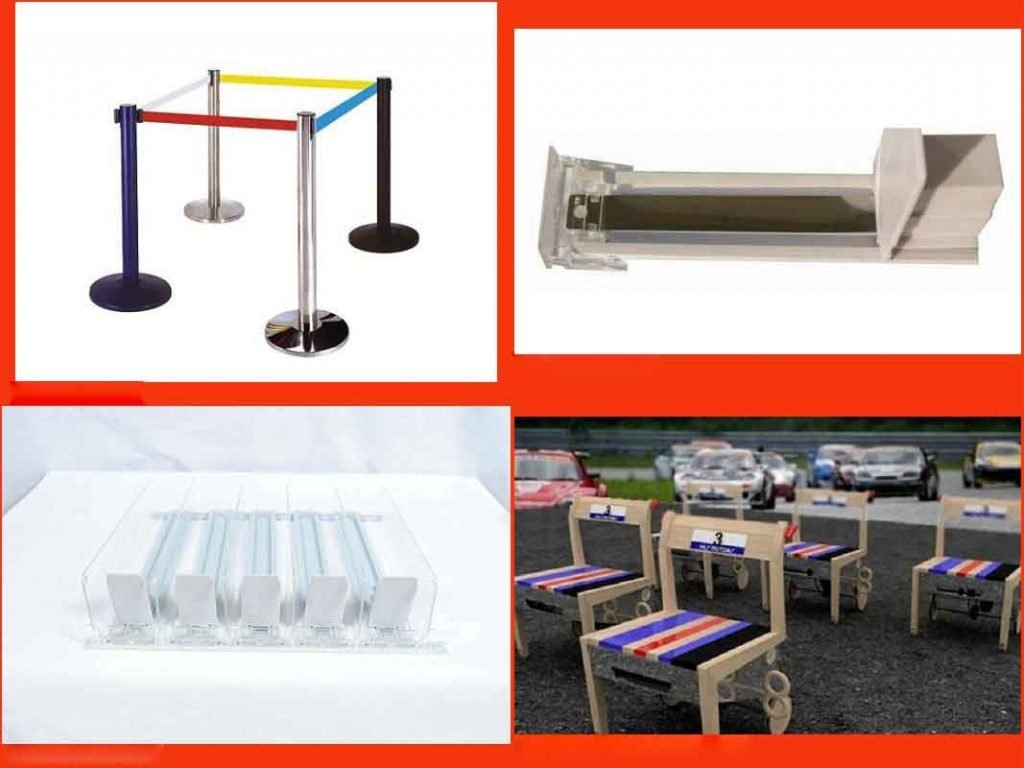

Application fields: coil tube clock toy can pull earplug mouse vacuum power cord, car seat belt electrical winding wire automatic rotating power device.

It is a rare tool for improving product performance and designing a new product design.

Manufacturing range: thickness 0.06 ~ 0.5 mm and width 1.0 ~ 50 mm.