OEM Torsion Spring

| Material | Spring Steel |

|---|---|

| Wire Diameter | 0.03mm-12.0mm |

| Surface Treatment | inc plated, nickel-plated, chrome-plated… |

| Application | Automotive, electrical equipment, household appliances, furniture… |

| Packing | The inner packing with plastic bags and outer packing with cartons |

| MOQ | 1 |

| Certificate | ISO9001:2015, SGS, ROHS |

Details about OEM Torsion Spring

What’s Torsion Spring?

A torsion spring is a kind of cylindrical helical spring that bears torque. It offers resistance to externally applied loads through angular deflection of the spring’s ends.

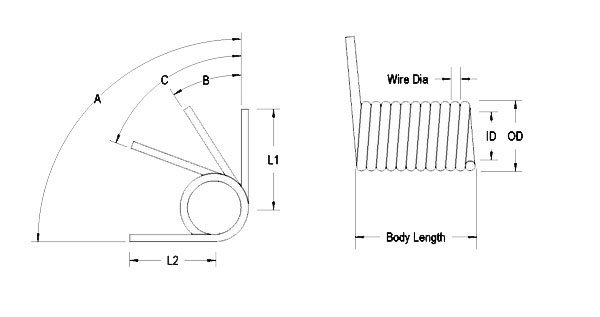

Torsion Spring Drawing

KEY PRODUCT HIGHLIGHTS

– USAGE: Torsion springs are helical springs that apply a torque or rotary force and offer resistance to externally applied loads

– OD: Outer diameter of the spring

– WIRE DIAMETERS: Wire diameter .0.03mm to 12mm

– TOTAL COILS: Number of active coils plus the end coils

– FORCE: Store and release angular energy

– DIRECTION OF WIND: left or right hand

– DEFLECTION ANGLE: The movement of spring ends under the application or removal of an external load

– SPACING: Can be built with tight coils or spaced out coils to reduce friction

– WIRE MATERIALS: Torsion springs are made from music wire, hard drawn, stainless steel, phosphor bronze, and more.

– CONFIGURATION: Spring legs can be bent, hooked, or formed to conform to custom application

MATERIALS, USAGE & SPECIFICATIONS

We commonly use carbon steel, stainless steel, copper-based, and titanium for custom products. To view our full materials list, click on the click below.

Surface Treatment

Electroplate: nickel, zinc, gold, silver, copper…(*ROHS and REACH standard)